Nobody wants to deal with damp and musty sound foam. Not only does it pose a threat to your health, but these bad working conditions can also cause mental strain and cause you to be less effective at work.

Now, whether you’re a musician, podcaster, or avid sound enthusiast, properly drying your sound foam is crucial for maintaining its effectiveness and longevity.

In this article, we’ll explore the best techniques and tips for ensuring your sound foam stays dry and mold-free.

Understanding the Moisture in Sound Foam

Before we delve into the techniques for drying sound foam, it’s important to understand why moisture is a concern in the first place.

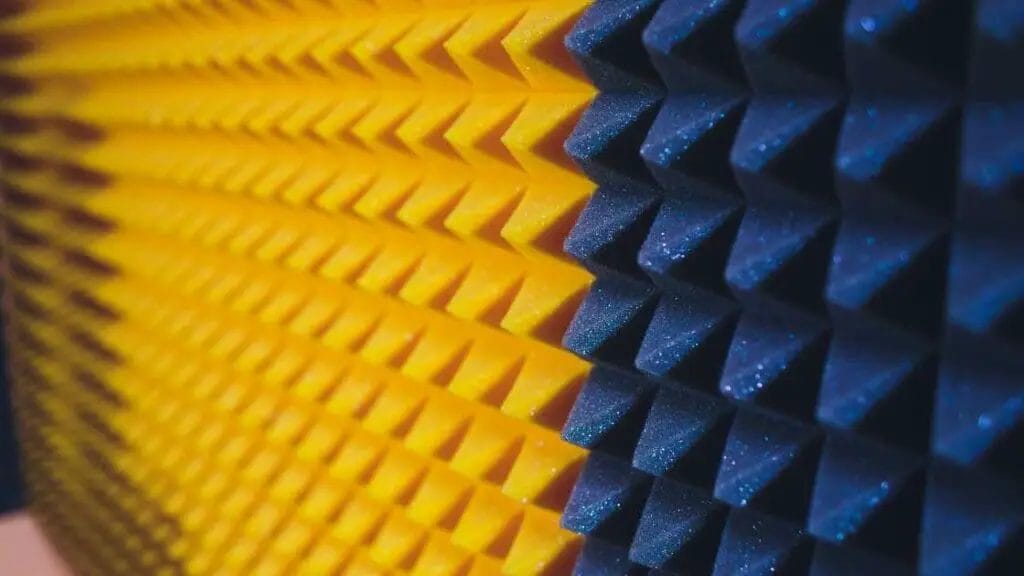

Sound foam, also known as acoustic foam, is designed to absorb sound waves and reduce echo and reverberation. However, sound foam is made of porous materials that can absorb moisture from the air.

When sound foam becomes damp, it not only loses its ability to effectively absorb sound but can also become a breeding ground for mold and mildew.

This not only compromises the quality of your sound but also poses potential health risks. Therefore, it’s essential to ensure your sound foam remains dry and mold-free.

Why is it Important to Dry Sound Foam?

Drying sound foam is crucial for several reasons.

Firstly, damp sound foam is less effective at absorbing sound waves.

This means that if your sound foam is not properly dried, you may experience reduced sound quality and increased echo or reverberation in your recording or listening space.

Secondly, moisture can lead to the growth of mold and mildew on sound foam.

Mold and mildew not only produce an unpleasant musty odor but can also cause allergies and respiratory issues.

To maintain a healthy environment and prevent potential health risks, it’s vital to keep your sound foam dry.

Methods to Dry Sound Foam Effectively

Now that we understand the importance of drying sound foam, let’s explore the best methods for achieving optimal dryness.

Natural Drying

One of the simplest and most cost-effective ways to dry sound foam is to let it air dry naturally.

Start by removing the damp sound foam from your recording or listening space and place it in a well-ventilated area. Ensure that there is adequate airflow around the foam panels.

To expedite the drying process, you can gently squeeze the foam panels to remove excess moisture.

However, be careful not to apply too much pressure, as this may deform or damage the foam.

Regularly rotate the foam panels to ensure even drying.

Using a Dehumidifier

If you’re dealing with high humidity levels, using a dehumidifier can be an effective solution for drying sound foam.

A dehumidifier works by removing excess moisture from the air, which helps in drying out the foam panels.

Place the dehumidifier in the room where your sound foam is located and set it to the appropriate humidity level.

The dehumidifier will continuously extract moisture from the air, speeding up the drying process of the foam panels.

Remember to regularly empty the water tank of the dehumidifier to prevent overflow.

Using a Fan or Air Conditioner

Another method to dry sound foam is by utilizing a fan or air conditioner. Both of these devices help in increasing air circulation and reducing humidity, which aids in drying out the foam panels.

Position a fan or air conditioner in the room where your sound foam is placed. Direct the airflow towards the foam panels to facilitate the drying process.

Adjust the fan or air conditioner settings to achieve the desired airflow and temperature for efficient drying.

Applying Heat

Applying heat can also help in drying sound foam effectively. However, it’s important to exercise caution to prevent damage to the foam panels.

Using a hairdryer on a low heat setting, gently blow warm air over the damp foam panels.

Keep the hairdryer at a safe distance from the foam to avoid overheating or melting.

Move the hairdryer in a sweeping motion to evenly distribute the heat.

Alternatively, you can use a space heater to warm up the room and expedite the drying process.

Precautions and Considerations when Drying Sound Foam

While drying sound foam, it’s essential to take certain precautions to ensure the safety and longevity of the foam panels.

- Avoid using excessive heat, as it can cause the foam to melt or deform.

- Do not place the foam panels near open flames or heat sources.

- Always follow the manufacturer’s guidelines for drying sound foam.

- Regularly clean and maintain your sound foam to prevent dirt and dust buildup.

By following these precautions, you can effectively dry your sound foam without compromising its quality.

Common Mistakes to Avoid when Drying Sound Foam

When it comes to drying sound foam, there are a few common mistakes to avoid to ensure optimal results.

One common mistake is using excessive force when squeezing the foam panels.

Remember to be gentle and apply only enough pressure to remove excess moisture. Applying excessive force can lead to deformation or damage to the foam.

Another mistake is neglecting to rotate the foam panels during the drying process. Rotating the foam ensures that all sides dry evenly, preventing the growth of mold or mildew in localized areas.

Lastly, avoid rushing the drying process. It’s important to give the foam panels ample time to dry thoroughly.

Rushing the process may result in residual moisture, leading to mold growth and compromised sound quality.

How Long Does it Take to Dry Sound Foam?

The time it takes to dry sound foam can vary depending on several factors, including the humidity level, airflow, and thickness of the foam panels.

In general, natural drying may take anywhere from 24 to 48 hours, depending on the surrounding conditions.

Utilizing a dehumidifier or fans can significantly reduce drying time. If you’re using heat, be sure to monitor the foam panels closely to prevent overheating.

To ensure that your sound foam is completely dry, it’s recommended to touch the panels and check for any residual moisture before reinstalling them in your recording or listening space.

Tips for Maintaining Dry Sound Foam

Once you’ve successfully dried your sound foam, it’s important to implement certain practices to maintain its dryness and longevity.

- Regularly inspect your sound foam for any signs of dampness or mold growth.

- Clean your sound foam regularly to remove dust and dirt that can trap moisture.

- Monitor the humidity levels in your recording or listening space and take appropriate measures to control it.

- Store your sound foam in a dry, well-ventilated area when not in use.

- Consider using moisture-absorbing products, such as silica gel packets, near your sound foam to prevent excess moisture buildup.

By following these tips, you can ensure that your sound foam remains dry and in optimal condition for long-lasting performance.

Alternative Options to Dry Sound Foam

In addition to the methods mentioned above, there are a few alternative options you can consider to dry sound foam.

One option is using a vacuum cleaner with a brush attachment to gently remove excess moisture from the foam panels. Ensure that the vacuum cleaner is set to a low suction power to avoid damaging the foam.

Another option is using moisture-absorbing products specifically designed for sound foam.

These products, such as foam-specific desiccant bags or moisture-absorbing crystals, can help in removing excess moisture and preventing mold growth.

Remember to thoroughly research and follow the manufacturer’s instructions when using alternative options to dry sound foam.